The real challenge lies in writing a new operating manual and that is where the experience of the process engineer comes into fore.

In this blog entry I have tried to put across general guidelines on preparing a plant operating manual based on my experience of writing a few of them. These guidelines are generic in nature and do not subscribe to any company philosophy for writing an operating manual.

Let us begin the exercise with what are the basic minimum requirements to start writing an operating manual

Following input documents are required during preparation of Operating Manual:

a. Basis of Design – Process Description

b. Process & Utility Flow Diagrams (PFDs and UFDs)

c. Piping & Instrument Diagrams (P&ID’s)

d. Deatiled process description from "Technology Licensor" for proprietary processes if applicable

e. Operating and Miantenance manuals of vendor equipment and packages (e.g. Instrument Air Package, Compressor Systems, Pumps, Water Treatment Plants, Fired Heaters etc.)

f. Function logic narrative provided by Instrumentation

Procedure:

Operating Manual is generally a Microsoft Word document.

Structure:

The Operating Manual is a structured document with a particular narrative style. The following is the sequence of the document:

- Coversheet with project title and document name i.e. Operating Manual

- 1st sheet with project title, document name i.e. Operating Manual

- List of Contents which includes:

. Abbreviations and Definitions

. Introduction which provides an overview of the project

. Process & Utility System Description

. Process Control and Automation

. Equipment Description

. Start-Up Procedure

. Normal Operating Procedure

. Shutdown Procedure

. Health, Safety & Environment (HSE)

. Appendices

Abbreviations & Definitiions:

The abbreviations and definitions of terms used in the entire document are summarized here.

Introduction:

This section provides the brief overview of the project which includes the purpose of the facility and what it contains.

Process & Utility System Description:

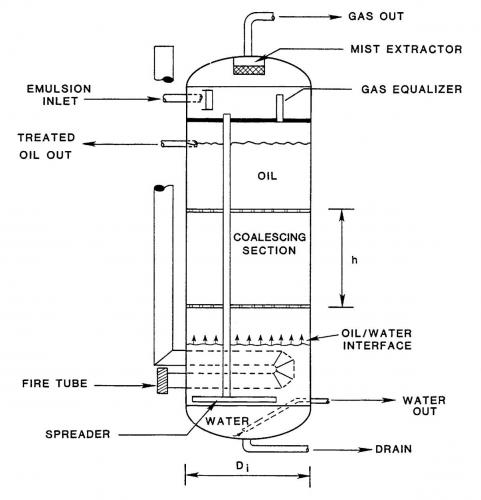

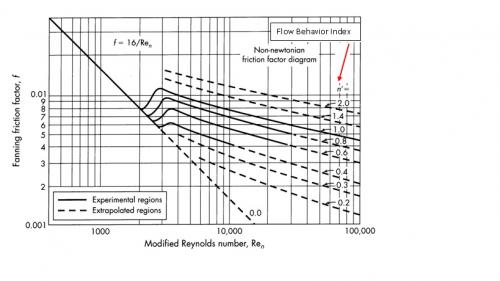

This section describes in detail the overall facility. The narrative should be in such a manner that the description is in the correct sequence of the process for easy understanding. Utility systems which supplement the main process should be described as a separate sub-section. Wherever possible, process description should be supplemented by simple sketches showing the major equipment and process control for a particular unit operation. This enhances the understanding of the process.

Process Control & Automation:

This section provides the description of the overall controls required for the safe, reliable and uninterrupted operation of the plant / unit. This could include flow, pressure, temperature and level control of the plant / unit for the smooth operation of the plant / unit. Controls required for start-up, planned shutdown and to change plant / unit capacity should be mentioned. High and Low alarms for process operating parameters are also described in this section.

Plant section-wise or unit-wise control systems should be addressed in a sequential manner in order to explain the process control in continuity.

All process safety and shutdown interlocks, automation provided for emergency shutdown of entire plant or unit of the plant should be described in this section. An example of an emergency shutdown could be the description of the Fire and Gas Monitoring system which initiates the plant or unit shutdown.

Tag numbers of instruments used for process control and automation should be mentioned for sake of clarity.

Equipment Description:

This section provides the functional description of the individual equipment or group of equipment which form a unit operation in the overall context of the entire facility. Description could include operating and design conditions for the individual equipment.

Providing tag nos. for the equipment is recommended.

Wherever possible, sketches are recommended for the sake of clarity.

Start-up Procedure:

This section provides the description of the start-up procedure for the plant / unit under consideration:

The first sub-section of this section should address the readiness of the plant to be started-up. By readiness it is meant that the plant / unit is ready to accept the process or utility fluid, raw materials or reactants. This requires that the commissioning check-lists prepared for the plant / unit are ticked off and signed off by the start-up team. A list of the check-lists may be provided in this section which have been signed-off to indicate readiness.

The second sub-section should address the start-up of the utility systems prior to the start-up of the main process. Utility systems could include charging up headers for instrument air, cooling water, inert gas for blanketing / purging etc.

The third sub-section should address the start-up of the main process. This section should describe the valves (manual or automated) and instruments to be lined up for introducing the process fluid (e.g. hydrocarbons, chemicals) into the equipment or equipments (e.g. piping, vessels, tanks, reactors) of the plant / unit being started up.

Wherever applicable, reference of vendor documents for any equipment / package unit should be provided in this section.

Normal Operating Procedure:

This section provides the description of the normal operation of the plant / unit and indicates the parameters to be monitored for maintaining the product quality and operational reliability of the plant / unit.

Operating parameters should be mentioned for a particular equipment or unit or the entire plant in this section. Sketches describing the normal operation are recommended for the sake of clarity. Field logging and maintaining history records of critical process parameters from the DCS or SCADA need to be mentioned in this section. Requirements of manning a particular plant section or unit should be mentioned in this section including field monitoring intervals by operating personnel for a particular equipment or unit.

While describing any operation it is recommended that equipment, instrument and line tag nos. be mentioned for the sake of clarity.

Shutdown Procedure:

This section provides the description of the shutdown procedures to stop the operation of the plant.

The first sub-section of this section deals with normal shutdown due to either scheduled maintenance and / or inspection or modification / de-bottlenecking of the plant. In this sub-section, description should be provided for planned reduction / removal of inventory of the process fluids from the equipment or unit to be shutdown. This would include stoppage of fresh feed, gradual reduction of plant / unit throughput to minimise off-specification product and final draining and purging of the equipment / unit for the purpose of complete emptying prior to handing over for maintenance / inspection or modifications / de-bottlenecking.

The second sub-section deals with emergency shutdown procedures due to any emergency such as an external fire, water flooding, earth quake, loss of containment of process fluid (gas or liquid leak) etc. In this section description should be provided for the methods for isolation of equipment or unit due to either manual initiation or automatic initiation of an emergency. Manual initiation is emergency initiated by the operator of the plant / unit whereas automatic initiation is emergency initiated by automatic detection of an emergency such as detection of fire or gas leak by an automated Fire & Gas detection system.

Usage of tag nos. for equipment, valves and instruments while providing the shutdown procedure description is recommended.

Health, Safety & Environment:

This section describes the HSE aspects of the facility that need to be considered.

Health:

This sub-section relates to the health of the people and working in the plant or living in the vicinity of the plant whose health should be a concern for the management of the plant. This should also address the health and well being of animals and other living organisms present in the vicinity of the plant, for e.g. marine life in any water body which would be effected by the operations of the plant.

In this sub-section a brief description of toxicity of the chemicals used in the plant / unit, acceptable noise levels for humans and other animals, magnitude of injuries due to fire and explosion, first aid measures for treating injuries etc. should be provided.

Safety:

This sub-section relates to the safe start-up, operation and shutdown of the plant during its entire lifetime. This section should address the normal hazards those are encountered in day-to-day operations of the plant. This section should also address the safety measures available to prevent any accident.

Some of the normal hazards could be loss of containment of any hazardous fluid due to overflow, leak or rupture, static electricity build-up, accidental fall from heights, burns due to exposure to hot surfaces, exposure to toxic fluids while collecting samples and piling up of flammable solid waste (wood, paper, cloth etc.).

Description of safety measures should include:

- Special operating procedures for activities like sample collection and regular maintenance of rotating machinery

- Issuance of work permits for hot work and vessel entry

- Usage of personal protective equipment (hard hats, safety shoes, eye goggles, ear muffs, breathing apparatus etc.)

- Provision of field sign boards indicating the type of hazard

- Regular house-keeping

- Emergency evacuation procedures

Environment:

This sub-section describes the limits for discharge of hazardous solid, liquid and gaseous effluents to the environment based on local laws and regulations and procedures for compliance to them.

Appendices:

The appendices should preferably include the list of Process & Utility Flow Diagrams (PFDs / UFDs), Piping & Instrument Diagrams (P&IDs), Cause and Effect Diagrams (CEDs) and reference vendor documents, table for Alarm / Trip setpoints and lubrication schedule.

The above mentioned guidelines should help a process engineer to get started on a plant operating manual.

Readers of my blog are welcome to provide their experiences of writing a plant operating manual and I look forward to their comments and observations.

Regards,

Ankur.